مربى التوت الارضي,

المقادير :

1 كغم توت ارضي مغسول

700 غرام سكر

1 كغم توت ارضي مغسول

700 غرام سكر

1 ليمونه او ملعقه صغيره ملح اليمون

10 غرام مادة البكتين "تباع في الصيدليات "

1 كاس ماء صغير

10 غرام مادة البكتين "تباع في الصيدليات "

1 كاس ماء صغير

- طريقة العمل:

في وعاء نضع السكر وكاس ماء واليمون ونضعهم فوق النار حتى يذوب السكر ثم نضيف التوت والبكتين ونتركهم حتى النضج بين كل فترة وفترة ننزع الرغوه من فوق المزيج , بعد النضج يحفظ في اواني محكمة الاغلاق وعند فتح اي عبوة يجب حفظها في الثلاجة - صحتين وعافيه .

في وعاء نضع السكر وكاس ماء واليمون ونضعهم فوق النار حتى يذوب السكر ثم نضيف التوت والبكتين ونتركهم حتى النضج بين كل فترة وفترة ننزع الرغوه من فوق المزيج , بعد النضج يحفظ في اواني محكمة الاغلاق وعند فتح اي عبوة يجب حفظها في الثلاجة - صحتين وعافيه .

تصنيع المربي تجاري

----------------------

يتم أولا تجهيز الخام من الفاكهة

===================

ويكون ذلك فى الموسم الخاص بكل فاكهة فكمثال

المشمش

-----------

يتم فرزه أولا وتقطيع الثمار الى أربع أرباع مع ازالة النواة وتكون المعاملة كالاتى

أولا بمحلول بارد من الستريك بنسبة 1%أى 1كجم لكل 100كجم ماء ثم يعامل بعد ذلك فى محلول ساخن من ميتا باي

سالفيت والستريك والاسكوربيك والجميع يكون باجمالى نسبة 1%

ثم يعامل مباشرة بمحلول من الاسكوربيك 1% ويكون بارد

ويتم وضع المشمش بعد ذلك فى أكياس زنه 5-10 كجم ويتم ادخاله تجميد سريع

أما بالنسبة للتجهيز

-----------------------

يتم فك الفاكهةأولا من التجميد مع وضع السكر فى حلة الطبخ ورفع درجة الحرارة الى تمام السوى ويتم سحب الخليط الى

الفاكيوم مع تشغيل الفاكيوم ورفع الحرارة الى 70 درجة وبعد ذلك يضاف البكتين ويتم بخلطه مع 3 أضعافه من السكر حيث

لايضاف كل السكر مع الخليط أولا وبعد ذلك يضاف الستريك الى الخليط حتى تمام النضح والوصول للبركس المطلوب ويكون

أعلى من 55% ويتم التعبئة بعد فصل الفاكيوم

وللعلم يضاف مادة حافظة بنزوات

لاتستخدم المواد الحافظة في حالة التصدير

تخزين الفواكه

الفاكهة او الخضر ------------درجة الحراره فهرنهيت -------الرطوبة النسبية -------مدة التخزين باليوم-------- نقطة التجمد

------تفاح----- ----------------(30---- 32 )----------- (85-----88-)-------------------------------------------28.4

-----مشمش-------------------(-31------32)-------------80-----85---------------7------14-------------------28.1

-----موز----------------------(56------60)-----------(90-----95)-------------(7-----10)----------------------

------تمر ------------------------(0-------24)------------(---------)--------------(365)-------------------------4.1

------تين--------------------------(31------32)------------(85----90)--------------(10)-------------------------------

-----عنب -------------------------(30-------31)----------(85------90)------------(-90----180)------------------24.9

-----ليمون-------------------------(55------58)----------(85----90)---------------(30-----120)-----------------28.1

-----بصل---------------------------(32------)--------------(70-----75)-------------(180----240)-----------------30.1

----بطاطس-------------------------(50-----70))-----------(85------90)-------------( 120)-------------------------28.9

الفاكهة او الخضر ------------درجة الحراره فهرنهيت -------الرطوبة النسبية -------مدة التخزين باليوم-------- نقطة التجمد

------تفاح----- ----------------(30---- 32 )----------- (85-----88-)-------------------------------------------28.4

-----مشمش-------------------(-31------32)-------------80-----85---------------7------14-------------------28.1

-----موز----------------------(56------60)-----------(90-----95)-------------(7-----10)----------------------

------تمر ------------------------(0-------24)------------(---------)--------------(365)-------------------------4.1

------تين--------------------------(31------32)------------(85----90)--------------(10)-------------------------------

-----عنب -------------------------(30-------31)----------(85------90)------------(-90----180)------------------24.9

-----ليمون-------------------------(55------58)----------(85----90)---------------(30-----120)-----------------28.1

-----بصل---------------------------(32------)--------------(70-----75)-------------(180----240)-----------------30.1

----بطاطس-------------------------(50-----70))-----------(85------90)-------------( 120)-------------------------28.9

Raw Materials

Jams and jellies are made from a variety of fruits, either singly or in combination. Most of the fruits are harvested in the fall. The level of ripeness varies. Pears, peaches, apricots, strawberries, and raspberries gel best if picked slightly underripe. Plums and cherries are best if picked when just ripe. The fruit is purchased from farmers. Most jam and jelly producers develop close relationships with their growers in order to ensure quality. The production plants are built close to the fruit farms so that the time elapsed between harvest and preparation is between 12-24 hours.

Sugar or high fructose corn syrup, or a combination of the two are added to the fruit to sweeten it. Cane sugar chips are the ideal type of sugar used for preserving fruit. Granulated and beet sugar tend to crystallize. Sugar is purchased from an outside supplier. High fructose corn syrup is processed by fermenting cornstarch. It is purchased from an outside supplier

The element that allows fruit to gel, pectin is present in varying degrees in all fruit. Apples, blackberries, cherries, citrus fruits, grapes, quinces, and cranberries have the best natural gelling properties. Strawberries and apricots are low in pectin. Jams made from such fruits are either blended with fruits high in pectin, or extra sugar is added to the mixture. Sometimes pectin is extracted industrially from dried apples.

Citric acid is added to obtain the correct balance needed to produce the jam or jelly. Lime and lemon juice are high in citric acid, therefore they are the most prevalent source used. Citric acid can also be obtained by the fermentation of sugars. It is purchased from outside suppliers.

Other flavorings, such as vanilla, cinnamon, mint, alcoholic beverages such as rum or Kirsch, can be added to the jam or jelly. These flavorings are purchased from outside suppliers.

The Manufacturing

Process

The ingredients must be added in carefully measured amounts. Ideally, they should be combined in the following manner: 1% pectin, 65% sugar, and an acid concentration of pH 3.1. Too much pectin will make the spread too hard, too much sugar will make it too sticky.

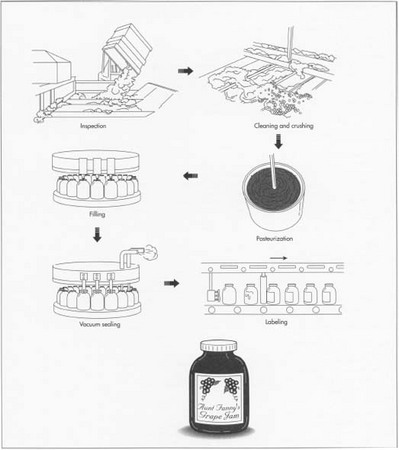

Inspection

- 1 When the fruit arrives at the plant, it is inspected for quality, using color, ripeness, and taste as guides. Fruit that passes inspection is loaded into a funnel-shaped hopper that carries the fruit into pipes for cleaning and crushing.

Cleaning, crushing, and chopping

- 2 As the fruit travels through the pipes, a gentle water spray clears away surface dirt. Depending on whether the finished product is to be jam or jelly, paddles push the fruit and or just its juice through small holes, leaving stems and any other excess debris behind. Some fruits, such as citrus and apples may be manually peeled, cored, sliced and diced. Cherries may be soaked and then pitted before being crushed.

Pasteurizing the fruit

- 3 The fruit and/or juice continues through another set of pipes to cooking vats. Here, it is heated to just below the boiling point (212° F [100° C]) and then immediately chilled to just below freezing (32° F [0° C]). This process, pasteurization, prevents spoilage. For jelly, the pulp is forced through another set of small openings that holds back seeds and skin. It will often then be passed through a dejuicer or filter. The juice or fruit is transferred to large refrigerated tanks and then pumped to cooking kettles as needed.

Cooking the jam and jelly

- 5 Premeasured amounts of fruit and/or juice, sugar, and pectin are blended in industrial cooking kettles. The mixtures are usually cooked and cooled three times. If additional flavorings are to be included, they are added at this point. When the mixture reaches the predetermined thickness and sweetness, it is pumped to filling machines.

Filling the jars

- 6 Presterilized jars move along a conveyer belt as spouts positioned above pour premeasured amounts of jam or jelly into them.

When the fruit arrives at the plant, it is inspected for quality, using color, ripeness, and taste as guides. Fruit that passes inspection is cleaned, crushed, and pasteurized. Next, the premeasured mixture is cooked with added sugar and pectin until it reaches the appropriate thickness and taste. Then it is vacuum-packed in jars and labeled.

When the fruit arrives at the plant, it is inspected for quality, using color, ripeness, and taste as guides. Fruit that passes inspection is cleaned, crushed, and pasteurized. Next, the premeasured mixture is cooked with added sugar and pectin until it reaches the appropriate thickness and taste. Then it is vacuum-packed in jars and labeled.

Metal caps are then vacuumed sealed on top. The process of filling the jars and vacuum packing them forces all of the air out of the jars further insuring the sterility of the product.

Labeling and packaging

- 7 The sealed jars are conveyed to a machine that affix preprinted labels. According to law, these labels must list truthful and specific information about the contents. The jars are then packed into cartons for shipment. Depending on the size of the producer's operation, labeling and packaging is either achieved mechanically or manually.

Quality Control

In the United States, food processing regulations require than jams and jellies are made with 45 parts fruit or juice to 55 parts sugar. The federal Food and Drug Administration (FDA) mandates that all heat-processed canned foods must be free of live microorganisms. Therefore, processing plants keep detailed lists of cooking times and temperatures, which are checked periodically by the FDA.

Requirements also exist for the cleanliness of the workplace and workers. Producers install numerous quality control checks at all points in the preparation process, testing for taste, color and consistency.

The Future

Because it is a relatively simple process, the production of jams and jellies is not expected to change dramatically. What is apparent is that new flavors will be introduced. Certain vegetable jellies such as pepper and tomato have been marketed successfully. Other, more exotic types including garlic jelly are also appearing on grocery shelves.

تعليق